本期向关注Aura3D的伙伴们展示了一款在Aura3D A5和A8颗粒3D打印机生产的定制化TPU枕头。它揭示了颗粒挤出、晶格设计和柔性材料如何协同工作,以解决传统枕头难以满足的实际人体工学和健康需求。

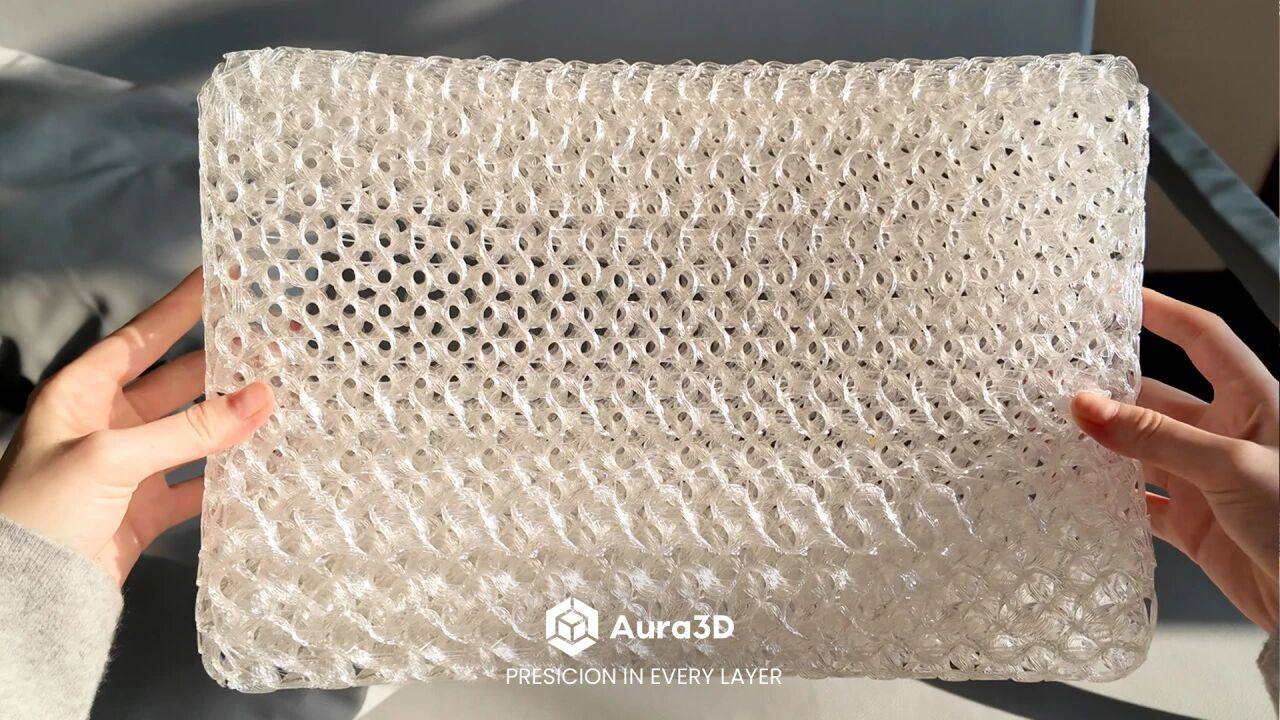

*一款在Aura3D A5和A8颗粒3D打印机上生产的TPUA枕*

应用背景:为何选择3D打印枕头

-

传统的泡沫或纤维枕依赖标准化模具,难以同时兼顾支撑性、透气性、耐用性和个体颈椎曲度。

-

基于颗粒的3D打印引入了一种新方法:数据驱动设计 + 晶格结构 + 柔性材料,使得枕头能够从批量产品转变为个性化的颈椎健康解决方案。

工作流程:从人体数据到功能结构

1) 3D扫描与参数化晶格设计

-

使用3D扫描设备获取头颈部几何形状,为个性化定制提供精确的解剖数据。

-

利用LuxStudio等参数化设计软件,将数据转化为多区域晶格结构。枕头的不同区域具有不同的晶格密度、支柱粗细和几何形态,从而在一个整体结构中创建出明确的支撑区和减压区。

-

在颗粒3D打印中,可根据功能需求应用多种晶格类型,包括蜂窝状、体心立方、面心立方以及其他基于梁或基于表面的结构。

-

对于可以用不同硬度打印的TPU枕,选用了螺旋状晶格结构。其连续的表面几何形态能够实现均匀的应力分布、负载下稳定的形变以及相互连通的空气流通通道。这种结构使枕头在提供均衡颈部支撑的同时,保持透气、回弹且抗永久变形——这些特性是传统泡沫设计难以实现的。

2) 打印工艺与参数参考

-

选择TPU颗粒是因其弹性、回弹性和耐用性,适合承受反复压缩而不产生永久变形。

打印机:Aura3D A5 & A8 颗粒3D打印机

材料:TPU 颗粒

喷嘴:1.0 mm

层高:0.5 mm

打印速度:50 mm/s

填充密度:9% 螺旋状晶格

打印时间:2-6 小时不等(根据晶格结构和喷嘴/层厚多因素)

模型尺寸:380 × 240 × 80 mm

-

Aura3D颗粒打印机也兼容路博润Lubrizol、万华WANHUA等供应商的工业级TPU,以及Aura3D的自研材料。

3) 性能与处理

-

打印完成后,枕头经过基本检查和机械性能评估,以确保:

稳定的弹性恢复

一致的层间结合力

可清洗性和结构完整性

颗粒3D打印在枕头应用中的优势

精准定制:完美匹配个体颈椎解剖结构。可根据用户反馈快速调整设计。

增强透气性:开放的晶格结构显著改善空气流通,减少热量和湿气积聚。

卫生易清洁:开放的晶格设计便于彻底清洗并快速干燥,可实现长期卫生使用——这是相对于传统泡沫枕的优势。

功能可调:支撑性、缓冲性和减压效果可通过晶格类型、密度和工艺参数精确控制。

可持续创新:兼容可回收和可生物降解材料,有助于减少材料浪费和环境影响。

通过集成3D扫描、参数化晶格设计、柔性TPU材料和基于颗粒的挤出技术,Aura3D A5和A8实现了新一代枕头的制造。这些枕头超越了普通舒适品的范畴,转向提供精准的颈椎健康解决方案——从标准化产品迈向数据驱动、功能化且可扩展的个性化定制。

Customized Cervical Pillow Solution Enabled by Pellet 3D Printing

In this case study, we present a customized TPU pillow produced on the Aura3D A5 & A8 pellet 3D printers, demonstrating how pellet extrusion, lattice design, and flexible materials work together to address real ergonomic and health needs that traditional pillows struggle to solve.

TPU pillow produced on the Aura3D A5 & A8 pellet 3D printers

1. Application Background: Why 3D Printed Pillows?

* Conventional foam or fiber pillows rely on standardized molds, making it difficult to balance support, breathability, durability, and individual cervical alignment at the same time.

* Pellet-based 3D printing introduces a new approach: data-driven design + lattice structures + flexible materials, enabling pillows to shift from mass products to personalized cervical health solutions.

2. Workflow: From Human Data to Functional Geometry

1) 3D Scanning & Parametric Lattice Design:

Head and neck geometry is captured using 3D scanning devices, providing accurate anatomical data for personalization.

Using parametric design software such as LuxStudio, this data is translated into a multi-zone lattice structure, where different areas of the pillow feature varying lattice density, strut thickness, and geometry—creating distinct support zones and pressure-relief zones within a single, integrated structure.

In pellet 3D printing, various lattice types can be applied depending on functional needs, including honeycomb, BCC, FCC, and other beam-based or surface-based structures.

For this TPU pillow, a gyroid (spiral-type) lattice was selected due to its continuous surface geometry, which enables uniform stress distribution, stable deformation under load, and interconnected airflow channels.

This structure allows the pillow to deliver balanced neck support while remaining breathable, resilient, and resistant to permanent deformation—capabilities that are difficult to achieve with traditional foam-based designs.

2) Printing Process & Parameters Reference

TPU-70A pellets are selected for their elasticity, resilience, and durability, making them suitable for repeated compression without permanent deformation

* Printer: Aura3D A5 & A8 pellet 3D Printers

* Material: TPU pellets

* Nozzle: 1.0 mm

* Layer height: 0.5 mm

* Print speed: 50 mm/s

* Infill: 9% gyroid

* Print time: 2-6 hours (Based on multiple factors such as lattice structure and nozzle/layer thickness)

* Model size: 380 × 240 × 80 mm

Aura3D pellet printers also compatible with industrial TPU from suppliers such as Lubrizol, Wanhua, as well as Aura3D’s in-house materials.

3) Performance & Post-Processing

After printing, the pillow undergoes basic inspection and mechanical evaluation to ensure:

* Stable elastic recovery

* Consistent interlayer bonding

* Washability and structural integrity

3. Advantages of Pellet 3D Printing for Pillow Applications

* Precision customization: Perfect alignment with individual cervical anatomy. Designs can be rapidly adjusted based on user feedback.

* Enhanced breathability: Open lattice structures significantly improve airflow, reducing heat and moisture buildup.

* Hygienic and easy to clean: The open lattice design allows for thorough washing and fast drying, enabling long-term hygienic use—an advantage over traditional foam pillows.

* Functional tuning: Support, cushioning, and pressure relief can be precisely controlled through lattice type, density, and process parameters.

* Sustainable innovation: Compatibility with recyclable and biodegradable materials helps reduce material waste and environmental impact.

By integrating 3D scanning, parametric lattice design, flexible TPU materials, and pellet-based extrusion, Aura3D A5 & A8 enable a new generation of pillows that move beyond comfort products toward precise cervical health solutions—from standardized products to data-driven, functional, and scalable personalization.

https://mp.weixin.qq.com/s/P3fCuHscKjA7iE9s5cfxXA?scene=1